silicone hose

-

Silicone Air Intake Hose For Automobile

Withstands extreme temperatures** **High temperature stability**: Silicone materials can withstand a temperature range of **-60°C to 200°C** for a long time: **Turbocharged area**: The temperature at the exhaust turbine end can reach **more than 150°C**, and the silicone hose is not easy to deform or age. **Cold start environment**: Maintains flexibility at low temperatures to avoid brittle cracking and leakage.

Email Details -

Automobile Oil Circuit Connecting Silicone Tube

Automobile oil circuit connecting hose is widely used and adaptable to multiple applications: it is widely used in automobile engine fuel supply systems, and can be connected to key parts from fuel tanks to fuel filters, fuel pumps and fuel injectors. Whether it is a traditional fuel vehicle, a hybrid vehicle or the auxiliary fuel system of some new energy vehicles, it can play an important role in ensuring smooth and safe fuel delivery, and ensuring the overall performance and driving safety of the vehicle.

Email Details -

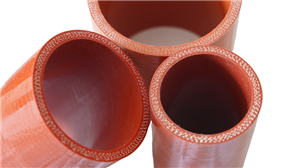

Aramid Fabric Reinforced Silicone Hose For Car

The aramid fiber sandwich consists of three parts: inner layer, reinforcement layer and outer layer: The inner layer is generally a silicone layer, which can directly contact the gas, liquid and other media to be transported, ensuring that the media does not leak and is not affected by the hose material. The reinforcement layer is woven from aramid fiber, which has the characteristics of high strength, high modulus, low elongation, excellent high temperature resistance, good chemical corrosion resistance, fatigue resistance and dimensional stability. The outer layer is usually also a silicone layer, which mainly plays a protective role, with weather resistance, ozone resistance, wear resistance, etc., to prevent the reinforcement layer and the inner layer from being eroded and damaged by the external environment.

Email Details -

Automotive Silicone Coolant Hose

In terms of performance, precise temperature control, excellent thermal stability and thermal conductivity help the engine maintain the optimal temperature at all times, improve efficiency and performance; low expansion coefficient reduces dimensional fluctuations caused by temperature changes, ensures tight connections and prevents leakage; high insulation prevents coolant current from interfering with the electrical system, enhancing safety; strong pulse resistance can cope with frequent fluctuations in coolant pressure, ensuring long-term stable operation of the cooling system. In terms of installation and maintenance, it is soft and bendable, adaptable to complex pipelines, easy and quick to install, saving time and labor costs.

Email Details