Automobile Engine Hose Assembly

Compared with ordinary pipes, the engine hose assembly has significant advantages. It is specially designed and optimized to better adapt to the complex and harsh working environment in the engine compartment, such as high temperature, high pressure, strong vibration and chemical corrosion. The engine hose assembly has higher reliability. After strict quality inspection and performance testing, it ensures stable operation throughout the life cycle of the vehicle, reduces engine shutdown and maintenance caused by pipe failure, improves the overall reliability and convenience of the vehicle, and lays a solid foundation for the efficient and stable operation of the engine.

As the circulatory system of vehicular powertrains, the Engine Hose Assembly plays a pivotal role in maintaining optimal engine performance through precise fluid management. This sophisticated network of interconnected components forms the backbone of the Automobile Hose Assembly system, ensuring seamless coordination between various engine subsystems while withstanding extreme operational conditions.

Structural Composition and Technical Specifications

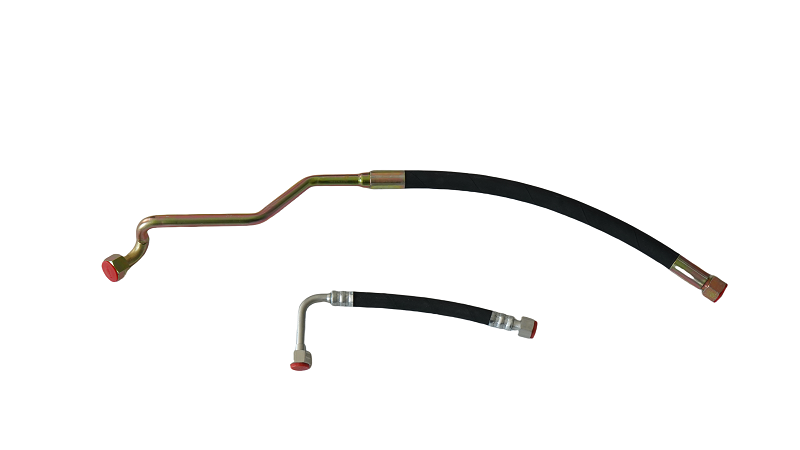

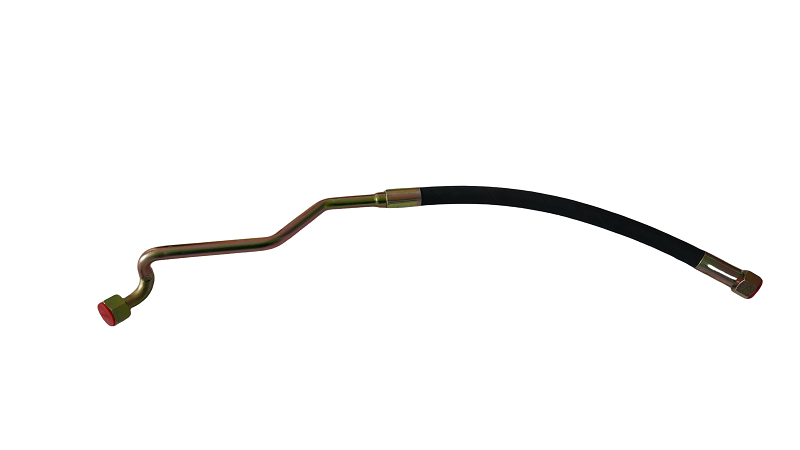

A typical Engine Hose Assembly comprises multiple specialized conduits designed for distinct functions:

Cooling System Hoses: Reinforced ethylene propylene diene monomer (EPDM) rubber tubes maintain stable coolant circulation, withstanding temperatures from -40°C to +150°C.

Fuel Delivery Lines: Multi-layer nylon/polyamide constructions with vapor barriers ensure precise fuel metering while preventing permeation losses.

Turbocharger Ducts: Silicone-based intake hoses with aluminum reinforcement collars endure boost pressures up to 3.5 bar.

Emission Control Tubing: Chemical-resistant fluorocarbon rubber (FKM) hoses handle hydrocarbon vapors and urea solutions in SCR systems.

Advanced Manufacturing Techniques

Modern Automobile Hose Assembly production incorporates cutting-edge technologies:

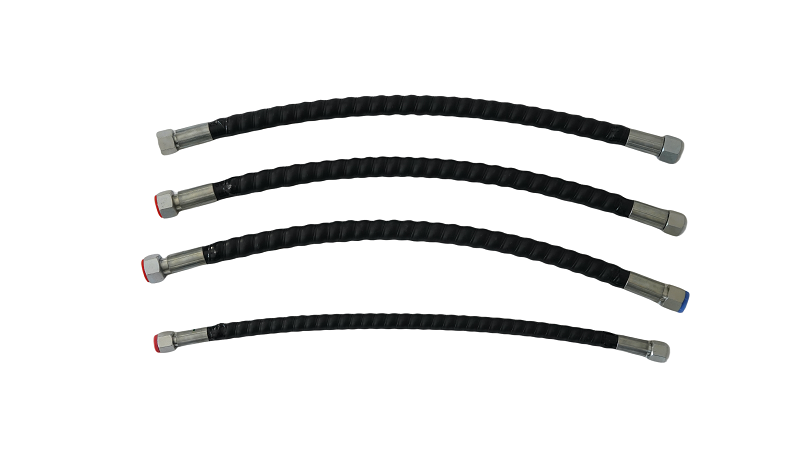

• Multi-axis braiding machines create 360° reinforcement layers

• Plasma surface treatment enhances bonding strength by 40%

• In-line pressure testing at 2.5× working pressure ensures reliability

• RFID tracking enables full lifecycle quality control

Performance Advantages

The Engine Hose Assembly delivers exceptional operational benefits:

Vibration Damping: Three-stage attenuation design reduces harmonic vibrations by 65%

Thermal Stability: Ceramic-impregnated sleeves protect against radiant heat exceeding 500°C

Chemical Resistance: PTFE liners maintain integrity in biofuel/E85 environments

Fatigue Resistance: Helical steel wire reinforcement enables 1M+ flex cycles

Application Versatility

This Automobile Hose Assembly solution adapts to diverse powertrain configurations:

✓ Traditional ICE vehicles (gasoline/diesel)

✓ Hybrid electric powertrains

✓ Alternative fuel systems (CNG/LNG/Hydrogen)

Quality Assurance and Compliance

Every Engine Hose Assembly undergoes rigorous validation:

• 500-hour thermal shock cycling (-40°C↔+140°C)

• SAE J20 R17 compliance for coolant hose standards

• ISO 11425:2017 certification for hydraulic systems

• REACH and RoHS environmental compliance

Maintenance and Service Life

Properly maintained Automobile Hose Assembly systems demonstrate:

8-10 year service life in standard operating conditions

50,000 km inspection intervals for commercial vehicles

Visual inspection protocols for bulge/swelling detection

Pressure decay testing for leak identification

Innovation in Material Science

Recent advancements in Engine Hose Assembly technology include:

► Graphene-enhanced composites improving thermal conductivity by 30%

► Self-healing elastomers automatically sealing <3mm punctures

► Smart hoses with integrated pressure/temperature sensors

► Bio-based rubbers reducing carbon footprint by 45%

The Engine Hose Assembly represents a critical investment in vehicular reliability and performance. By choosing certified Automobile Hose Assembly solutions, manufacturers and maintenance providers ensure compliance with global automotive standards while optimizing total cost of ownership. Through continuous R&D investment and precision manufacturing processes, modern hose assemblies have evolved into high-tech components that actively contribute to emission reduction, fuel efficiency improvement, and extended engine lifespan.

This comprehensive approach to Engine Hose Assembly design and production establishes new benchmarks for durability and system integration, solidifying its position as an indispensable component in contemporary automotive engineering. Whether for routine maintenance or performance upgrades, selecting the appropriate Automobile Hose Assembly remains crucial for achieving optimal powertrain functionality and regulatory compliance in today's rapidly evolving automotive landscape.