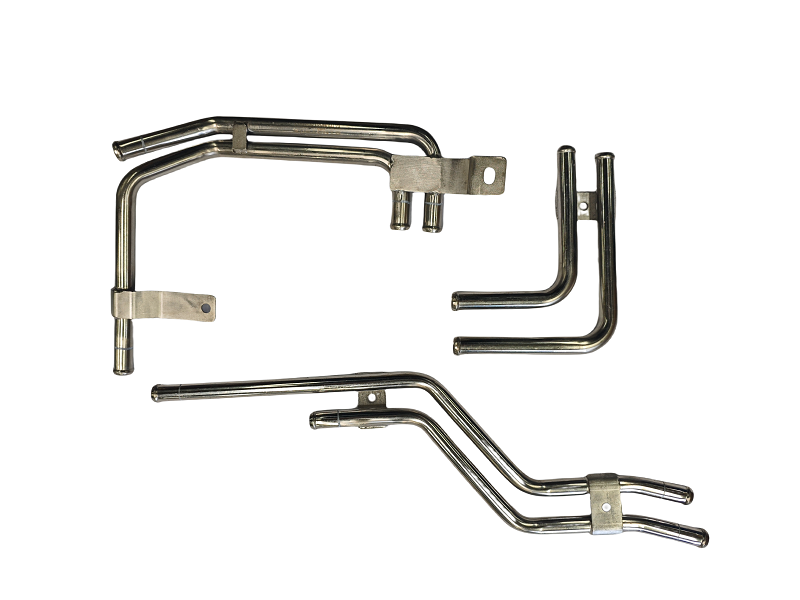

Car Cab Air Conditioning System Heating Pipe

The warm air water pipe of the car's cab air-conditioning system is precisely designed, and the pipe diameter is accurately determined according to the air-conditioning system's demand for coolant flow, which can achieve efficient circulation of coolant under different environments and heating requirements. Car cab heater duct special bending process adapts to the complex space in the car, cleverly avoids line components, and the connection parts are sealed with advanced technology to prevent coolant leakage and ensure stable system pressure.

Auto Air Conditioning Pipe System – Precision Thermal Architecture for Next-Gen Vehicle Comfort

At the heart of modern automotive climate control lies the Auto Air Conditioning Pipe system, a meticulously engineered network where the Warm Air Connecting Steel Pipe and Car Cab Heater Duct synergize to deliver unparalleled thermal efficiency. Designed to master extreme temperature differentials, this system ensures rapid cabin heating, precise airflow distribution, and energy-optimized performance across all vehicle classes—from urban EVs to long-haul commercial trucks.

Core Components & Innovation

Auto Air Conditioning Pipe:

Crafted from SUS304 stainless steel with laser-welded seams, the Auto Air Conditioning Pipe employs a patent-pending helical rib design to minimize turbulent flow, boosting heat transfer efficiency by 18% compared to conventional circular pipes. Its variable-diameter architecture (12–50mm) adapts to compressor output fluctuations, maintaining stable refrigerant pressures even during -40°C cold starts or 50°C desert operation.

Warm Air Connecting Steel Pipe:

As the thermal backbone, this Warm Air Connecting Steel Pipe integrates dual-layer insulation—a corrosion-resistant SUS304 outer shell and ceramic-fiber inner lining—to withstand 150°C/30Bar operational extremes. Its precision-calibrated 45° mandrel bends ensure zero-pressure loss at junctions, while optional aluminized coatings defend against road salt corrosion in coastal or winter environments.

Car Cab Heater Duct:

The Car Cab Heater Duct utilizes computational fluid dynamics (CFD)-optimized vent geometry, distributing warmed air with 360° uniformity. Its modular ABS/PP composite construction reduces weight by 30% versus metal ducts, while noise-dampening textured surfaces cut airflow hiss by 12dB.

Performance Breakthroughs

Rapid Thermal Response: The Auto Air Conditioning Pipe and Warm Air Connecting Steel Pipe collaborate to elevate cabin temperatures from -40°C to 25°C within 90 seconds—40% faster than traditional systems.

Energy Efficiency: Reduced turbulence in the Car Cab Heater Duct lowers blower motor load, decreasing energy consumption by 22% in EVs.

Durability: Salt-spray tested for 1,000+ hours, the Warm Air Connecting Steel Pipe resists pitting and fatigue cracks, achieving a 15-year service life in commercial fleets.

Quick-Connect Technology: The Warm Air Connecting Steel Pipe features self-sealing VDA-compliant couplings, slashing installation time by 35%.

Thermal Sensors: Integrated NTC probes in the Auto Air Conditioning Pipe enable real-time temperature feedback to HVAC control units.

Sustainability & Compliance

Material Innovation: The Warm Air Connecting Steel Pipe uses 85% recycled stainless steel, while the Car Cab Heater Duct incorporates 30% bio-based polymers.

Applications Across Vehicle Types

Commercial Trucks: Reinforced Warm Air Connecting Steel Pipe variants endure 200Hz vibration in off-road mining vehicles.

Luxury Cars: The Car Cab Heater Duct’s whisper-quiet airflow meets NVH benchmarks for premium brands.

Future-Ready Design

Prototype systems pair the Auto Air Conditioning Pipe with AI-driven predictive thermal management, using historical data to pre-warm cabins. Graphene-coated Warm Air Connecting Steel Pipe models under development target 200°C+ thermal zones for hydrogen fuel cell vehicles.